The method

Our philosophy

The Olinda oil mill follows the entire production cycle: from the plant to the bottle. A choice to guarantee maximum quality and offer maximum guarantees to the consumer. Our philosophy has never been to aim for large numbers, but to offer consumers and families who choose us a product of the highest level, a fair and correct quality-price ratio. Our target audience? Lovers of good traditional Italian cuisine, envied all over the world, but also those who prefer to experience the new flavors that our land offers.

We start from the field

What are the rules for producing a good extra virgin olive oil? The first thing to take care of is the raw material. Without healthy olives you cannot have a good oil. You must therefore start from the field: healthy olives are obtained from a healthy plant Harvesting must be done in the right period; extraction followed by due care and correct maintenance is important, as extra virgin olive oil must be protected from light, air and heat.

On the field we start in the spring with pruning and fertilizing. Between May and June, from the flowering and the legation, the first indications on the progress of the harvest are found. Between August and September, however, you must pay close attention to pests that can attack the fruit. The most dangerous enemy is the olive fly, which deposits the egg under the peel from which the worm then feeds, digging into the pulp. The struggle becomes more difficult for those who, like us, have chosen organic cultivation and therefore do not want to use chemical substances. In addition to the fly, attention must be paid to worms and mold. But don’t worry: even in organic farming there are methods and techniques to prevent and fight these insects that damage the quality of the product.

The decisive factor is the milling and extraction system. There are two methods: the oldest is the discontinuous system (also called a fiscoli), while the most modern systems are a continuous system (or a centrifuge).

The olive harvest

The olives must be harvested at the right time. Not all varieties ripen in the same period. Specialized plants, such as that of the Frantoio L’Olinda, allow you to organize the harvest at the right times and in the best way. Specialized plant means that the olive grove is divided into blocks, each of which are planted with plants of only one variety (cultivar) .This allows each individual cultivar to be harvested at the right moment of ripeness and to obtain mono-varietal oils.

The harvest is done strictly by hand, with the help of facilitators: the olives are placed in small boxes, perforated both below and laterally, to circulate the air. Why do we specify it? Because the arrangement in large crates (or the storage on a wagon or, worse still, in the body of a truck) would favor the formation of mold, the heating of the olives and the consequent internal fermentation of the grape. A process that raises the acidity rate of the oil.

The thing to avoid is the storage of the olives, that is, leaving them still for more than a day. The shorter the time between collection and milling the higher the quality of the oil. L’Olinda, thanks to the availability of the company oil mill, manages to drastically reduce these times (everything takes place in about three hours).

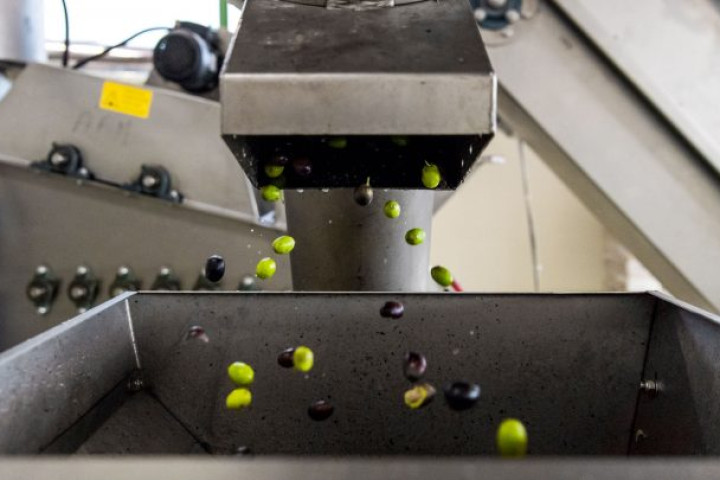

Once at the mill, the olives are washed and defoliated. In other words, twigs and leaves are removed. Some argue that it is good to add some leaves to make the oil greener, but it is not a good rule. The leaves, pressed together with the olives, increase the sense of astringency and change the taste of the oil, causing burning in the throat (not to be confused with the pinch of oil which is instead a basic characteristic in high quality oil). An excessive presence of twigs, however, gives the oil an unpleasant wooden flavor. The washing of the olives is necessary to remove all the substances present on the peel and any residual earth that would transfer a negative organoleptic sensation to the oil.

The Milling

Many still believe that the discontinuous system (with stone mills and “fiscoli”) is the best because it is” traditional “. But tradition does not always go hand in hand with quality. Old farmers looked above all at yield, that is, at the quantity of oil. They kept the olives for days and days in jute sacks or piled up in a room before taking them to the mill. A long storage period reduced the amount of water present in the grape and therefore the overall weight. With this method they saved on the cost of milling, but an oil with high acidity was obtained, greatly deteriorated in sensations and taste by the formation of molds and other pathogens.

With the discontinuous system, the olive is placed in a tank in which three stone mills rotate. The olive is crushed and reduced to a pulp by the mills that run for several minutes. The olive, through pressure and rubbing (pulp and bone) becomes a “paste”. This process has a series of drawbacks: mechanical crushing heats the pasta, contact with oxygen oxidizes it and being the tank open, the scents are dispersed in the air.

Today the most modern crushers are continuous cycle. The crushing of the olives does not take place in an open tank, but in a hammer crusher or, better still, with knives. That is, a faster, more hygienic, more flexible and better adaptable system is used to the characteristics of the olives and the oil to be obtained. The knife crusher breaks the olive berry in a split second and the “pasta” passes through a perforated grid. By reducing the size of the grill, an oil with a fresher and longer-lasting characteristics is obtained; using a grate with larger holes results in a sweeter oil. The peel also contains polyphenols, antioxidant substances that give freshness. The finer the skin is shredded, the more these components will end up in the oil.

Conservation is the last step, but equally decisive for maintaining the properties, characteristics and quality of the product. Unlike wine, oil does not improve over time. Indeed, if it is not stored according to the rules, it loses its characteristics and acquires a series of defects. Oil has three enemies: light, air and heat. It should therefore be kept away from light sources (steel containers or dark bottle), in a cool environment ( but not cold) in a closed container.

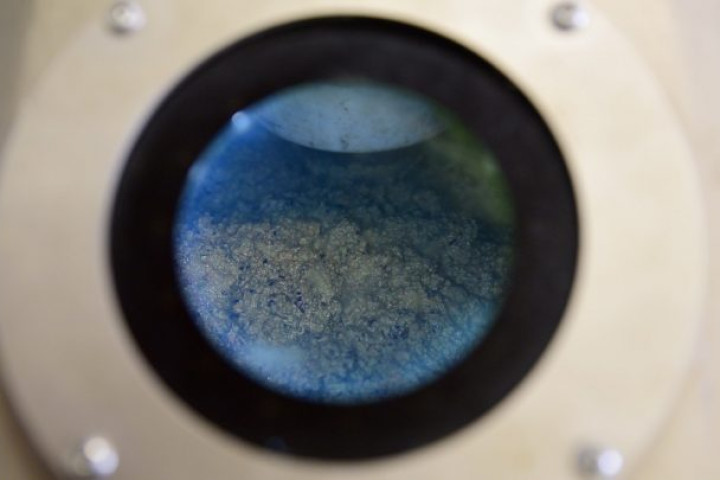

L’Olinda oil mill for the storage of its products has created an air-conditioned environment at constant temperature (14-16 °). The oil, filtered immediately after extraction, is stored in sealed stainless steel tanks under nitrogen. That is, an automated, compensation system has been created that introduces an inert gas (nitrogen) into the tanks. In practice, as the oil is extracted for packaging, the plant introduces nitrogen. In this way the oil is stored in the dark, at the right temperatures and in the total absence of oxygen. That is the ideal condition to keep all the organoleptic characteristics of the oil unaltered and as long as possible.

How to choose

The first rule is to try to understand what you are buying. Going directly to the oil mill, realizing the production processes is already a good guarantee. However, the best test remains your taste: the mouth is the best label. The good things are immediately noticeable. An extra virgin olive oil is never the same as that of the previous year.

The cultivars

In the Marche we have 21 indigenous cultivars, to which the two most common varieties are added, namely Leccino and Frantoio. L’Olinda, in the new olive groves, has planted almost all the varieties of the Marche: Raggia, Mignola, Rosciola dei Colli Esini, Coroncina, Piantone di Mogliano, Ascolana tenera, Lea, Nebbia del Menocchia, Nostrale di Rigali, Orbetana, Sargano and others. Monicella, a nearly disappeared variety from the Roveto Valley, in Abruzzo, a Slow Food presidium, has also been included in one of the last plants. From its olives a fine and aromatic oil is obtained, with a high content of phenolic and antioxidant substances.

Monovarietal oil

Monovarietal oils are obtained from a single olive cultivar. The market pushes more and more towards massification and uniformity. With monovarietal oils we want to combat standardization and flattening of taste. The quality is the same because the processing system is the same, but the goal is to recover and save aromas and perfumes that would be permanently lost.

Environmental care

Attention to the environment, the territory and the landscape are in the company’s DNA. Oil mill and farmhouse are self-sufficient from an energy point of view (they are powered by a 23 Kw photovoltaic system). Rainwater is collected in a large tank (about 300 cubic meters) and in two wells of 35 meters each. A precious resource, in periods of drought, for the vigor and life of the olive trees. During the processing of the olives, the hazelnut ( the woody part) which becomes a precious biomass (also for its caloric power) for hot food, stoves and burners. The structure is equipped with a complex treatment water purification system.